B processes include fabrication of sheet metal drilling turning milling grinding sawing and welding.

Risk assessment sheet metal folder.

Framework for metals risk assessment 2 1 2 1.

In the case of steel bending and tube bending for example there are a.

Mini formit 3 in 1 universal sheet metal machine.

Warco mini formit for bending cutting shearing and rolling truly a 3 in 1 sheet metal machine.

Plant and equipment risk assessment folder pan brake sheetmetal keywords.

Incident must be added to service risk register.

Understanding metal bending for your safety guest post metal bending is a production process in which the shape of sheet metal and tubes can be changed through plastic deformation.

Similar to the action of scissors the blade shears the material starting at one side of the sheet.

Heavy duty sheet metal box and pan folder.

This post will explain some safety tips that you need to take into account while using a sheet metal bending machine.

Ensure no slip trip hazards are present in workspaces and walkways.

Ensure that risk assessment has been read.

Locate and ensure you are familiar with the operation of the on off starter and where fitted lockable e stop.

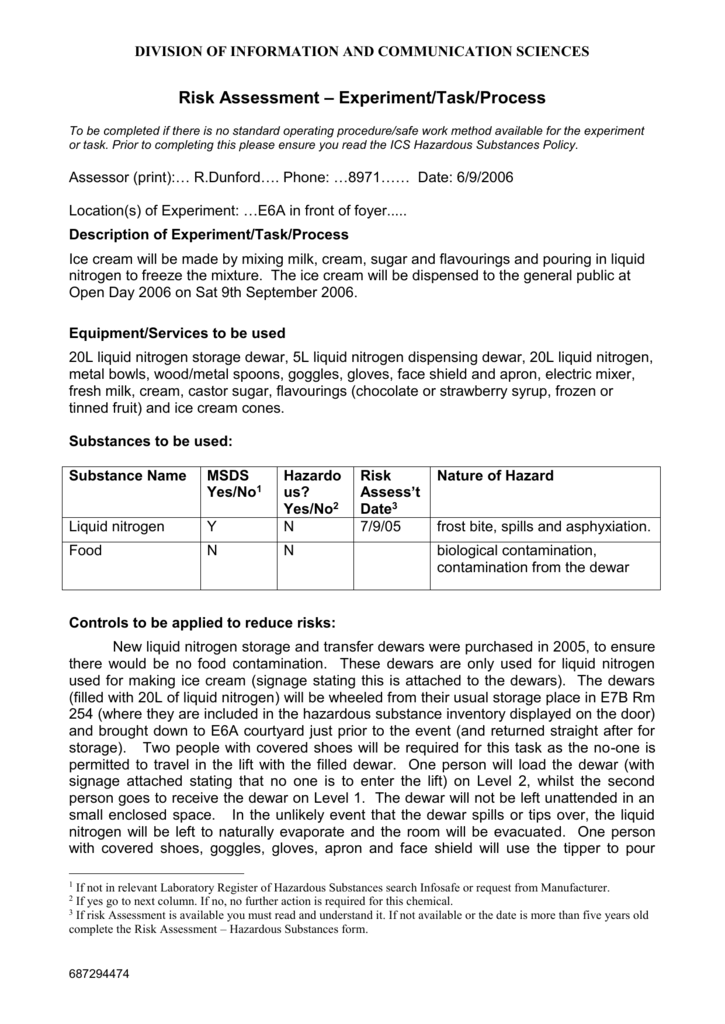

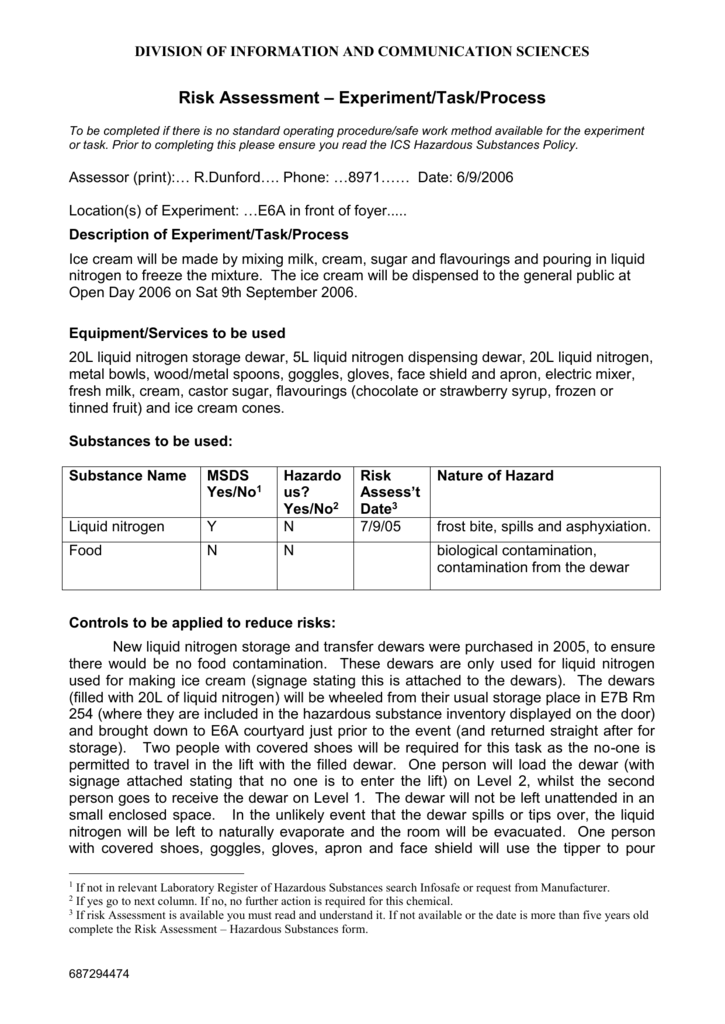

Hazard identification and risk assessment form produced by.

Sheet metal is considered to be one of the most versatile metals.

While this guidance has not been updated to reflect current work health and safety legislation the health and safety at work act 2015 and regulations it may still contain relevant information and practices to keep workers and others healthy.

Do not commence the activity until a risk assessment has been completed to ensure the safety of the situation or task.

1 2015 page 1 of 10 risk assessment.

Sheet metal date of assessment.

In certain types of bending such as tube bending and sheet bending a number of ways can be implemented to deform the metal.

When bending or folding light gauge sheet metal that is neither awkwardly small nor too large to manipulate as a single operator.

Check that all guards are in position.

If it is not.

8 hazards see workshop risk assessment 9 ways of containing the hazards.

See relevant coshh sheets.

Oak leaf safety ltd.

Human health and ecological risk assessment.

The latter refers to the fact that the material has undergone certain irreversible changes as a result of forces that have been applied to it.

This plant equipment risk assessment is to be monitored and reviewed annually for a further four 4 years.

Tim o sullivan oak leaf safety review date.

Mini slip rolls for sheet metal.

19th november 2015 undertaken by.

Uq risk assessment task id 1985.

Incident report must be completed.

November 2016 hazard recommended controls actions completion.